What is Power Take Off?

What is power take off? If one hasn't spent much time around farm tractors, we can imagine the images this could bring to mind! Might this refer to someone skedaddling at high speed to avoid approaching chore time? Or the neighbor kid's souped-up pick-up leaving in a cloud of dust? If so, you may be surprised to hear that it's a cool device that has turned a simple farm tractor into an amazing, multitasking enabler!

So Exactly What is Power Take Off?

What is power take-off? That is a great question! Let's explore it, and find out how power take-off works.

The power take-off on a John Deere tractor. It's located under the seat, between the arms of the 3-point hitch.

Source

The power take-off on a John Deere tractor. It's located under the seat, between the arms of the 3-point hitch.

SourceThe power take-off definition is: a device made up of gears, shafts, etc., that takes power off a tractor's running engine, transferring the harnessed energy to a separate, non-motorized attachment or implement. Since many pieces of agricultural equipment do not generate the power needed to operate, the PTO provides power for implement operation, enabling it to them to perform a wide spectrum of useful and necessary functions.

By the way, what is a PTO? We can tell you that it doesn't mean "paid time off", especially to a farmer! PTO is the commonly used acronym for "power take-off". Both the name and this acronym are used interchangeably.

Where is the Power Take Off Located on the Tractor?

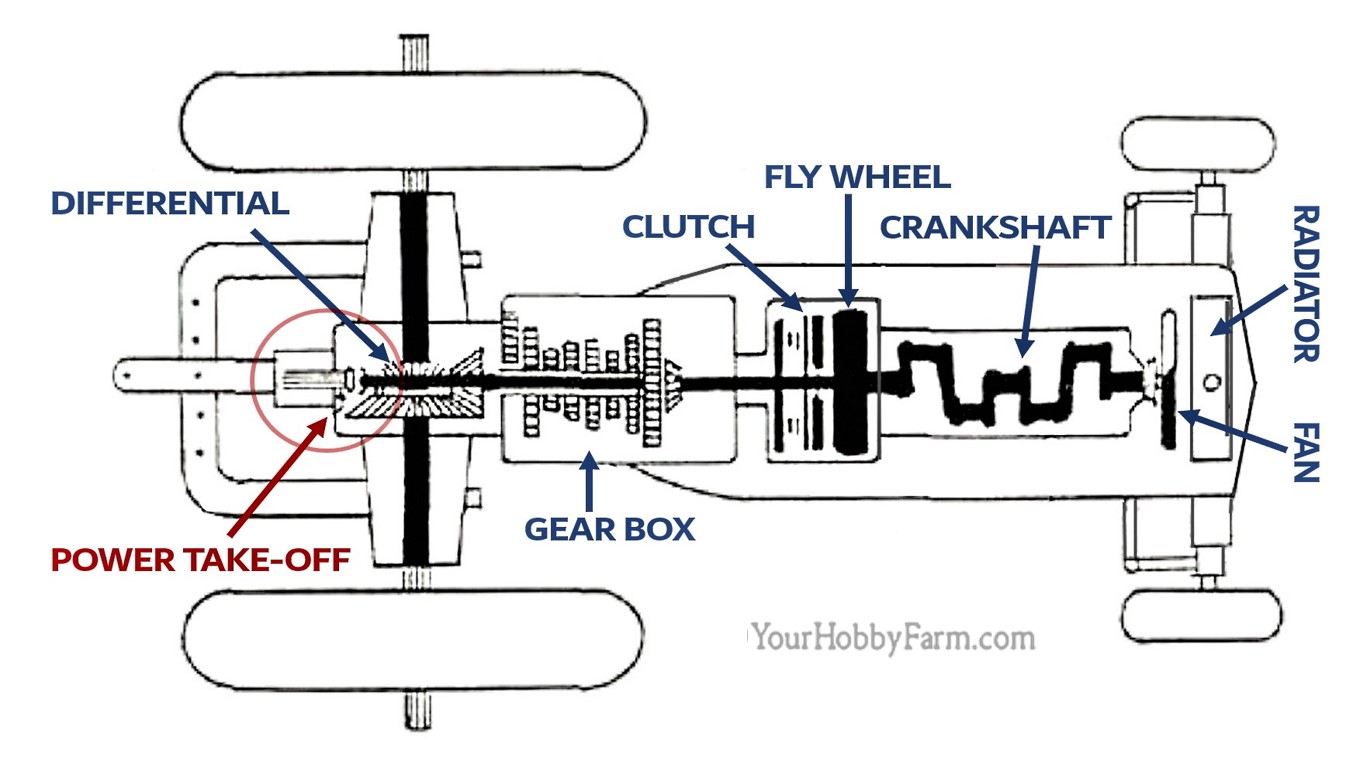

When answering the question, what is power take off, it's important to visualize where it's located on the tractor to help with the understanding of it's function. The power take-off is usually located at the rear end of a farm tractor, below the seat, between the arms of the 3 point hitch.

The PTO uses a splined driveshaft between the tractor and the implement. The transfer of power to the implement is accomplished by connecting a driveshaft from the machinery to the tractor's PTO stub shaft.

It's not common, but sometimes a PTO may be located under the belly of the tractor to power a mid-mount attachment such as a mower.

You may also find a PTO at the front of a tractor, sometimes modified from a rear power take-off. This enables the operator to face forward when using attachments such as a snow blower.

Splined shaft: A shaft having a number of equally spaced grooves cut into it to form a series of projecting keys which fit into an internally grooved cylindrical member, transferring torque to it.

Components of the Power Take Off Unit

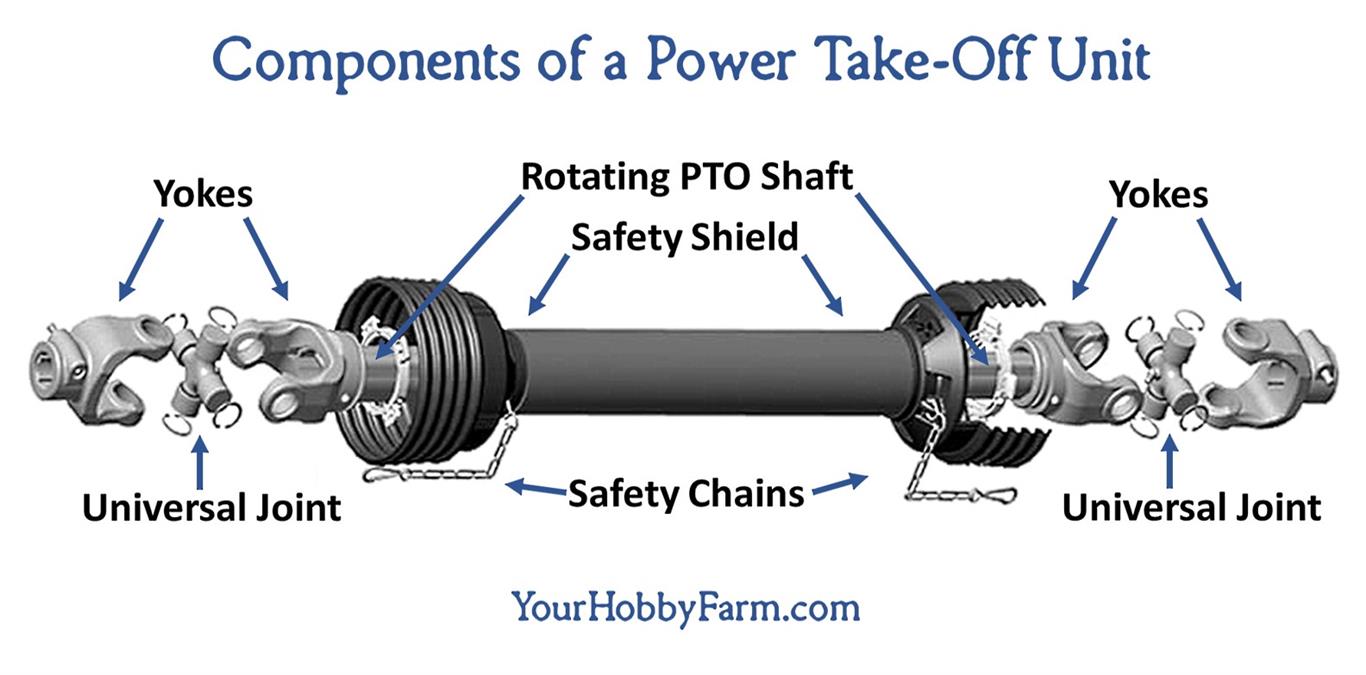

The power take-off is a driveshaft assembly that consists of several important parts. Together, this assembly joins a piece of equipment to the tractor to enable transfer of power.

The components of the PTO system on the implement connects directly to the tractor's 6-splined PTO shaft, or stub, between the arms of the 3-point hitch of the tractor.

A splined collar, which extends from the tractor differential, slides over the tractor's splined PTO stub. The spline collar is held in place by a spring-loaded pin which latches into a recess on the spline shaft of the tractor. In some cases, the implement also has a matching 6-splined shaft stub with a spline collar.

The PTO shaft which rotates rapidly, is made up of two telescoping pieces, one half fitting into the other (under the safety shield), enabling compression or expansion of the shaft with the movement of the tractor and implement when the implement is lowered or lifted.

On each end of the rotating PTO shaft are universal joints, or universal couplings, also called U-joints. These make the shaft work flexibly when lifting the implement off the ground, traveling over uneven ground, and in some cases, when the tractor and implement turn.

Each of these universal joints are held together and attached to the power take-off assembly by 2 yokes at each end of the shaft.

The heavy duty plastic safety shield, which surrounds, and is independent of, the turning PTO shaft, covers all the dangerous, rapidly rotating parts. A safety chain helps keep the plastic safety shield from spinning with the shaft that is inside it.

The spinning power take-off shaft rotates in proportion to the speed of the tractor's engine in a clockwise direction, when looking at it from the rear of the tractor, allowing the implement to draw power from the tractor's engine.

What is RPM, Horsepower, and Torque All About?

What is power take off's driving force? And what is 540 RPM and 1000 RPM when talking about a spinning power take-off shaft? What are the differences between the two, and why is it important?

First of all, what is RPM? RPM is the acronym for Revolutions per Minute. RPM is a unit of rotational speed or the frequency of rotation around a fixed axis. The number before RPM is the number of turns in one minute. The RPM used, or required, depends on the horsepower of the tractor and size of the implement.

What is Horsepower? Horsepower or HP, is a unit of measurement of power, or the rate at which work is done, usually in reference to the output of the engine. Horsepower is a factor of torque multiplied by speed. With X amount of torque on the PTO shaft, if it's turning at 1000 RPM, it is transmitting nearly double the horsepower of 540 RPM.

So, what is torque, and how is it related to horsepower? Torque is the measure, in foot-pounds (ft-lbs), of the force to rotate the body to which it is applied, causing an object to rotate on an axis. This determines the amount of work an engine can perform, while horsepower is the measure of how quickly that work can be done.

An older 50 or 60 HP farm tractor is limited to 540 RPM because the standard U-joints and the splined shaft connection can't handle the torque for more horsepower.

The horsepower of the PTO is directly proportional to the output shaft rotations per minute, therefore the faster it turns, the more horsepower is produced.

Here is the formula to calculate the speed of the PTO: Equipment Speed ÷ Engine Speed = PTO Speed.

The formula to determine the horsepower is: Horsepower (HP) = torque (T) x rpm ÷ 5,252.

Hopefully, this has helped to answer the question, "what is power take off?"

Here is more helpful info explaining these things in greater detail.

Different Power Take Off Types for Equipment Needs

There are three basic power take-off types. The type of PTO that you choose is determined by the implement used for the job you need to do. Whether mowing, plowing or snow-blowing, there is a PTO shaft type that is best for the job. This helps protect your machinery from unnecessary pressure, tension, or damage.

The Non-Shear type is designed with a solid yoke to yoke-set-up. This can be used for implements like large mowers where the movements are smooth and times of resistance or sudden stopping is not expected.

On the Shear Pin type of PTO, the end yoke is in two pieces held together by a shear pin which absorbs the shock if there is a sudden stop in motion. This avoids damage to the PTO shaft. A wood chipper, which can become suddenly blocked, wedged, or stuck, is an example where this is used.

A PTO with a Slip Clutch protects the tractor and attachment from being damaged by internal sliding, allowing movement when striking an object such as rocks and stones that have risen to the surface of the ground. The slip clutch absorbs the shock, protecting the gearbox from being damaged.

Putting the Tractor Power Take Off to Use

A tractor, by itself, is quite limited in what it can accomplish on a farm! It's kind of like owning a drill without drill bits!

Over the past 100 years or so, an extensive and diverse assortment of tractor attachments and implements have been created for tasks that had previously been done by hand. Not all of these time-and-labor-saving farm implements run off the rear engine power take-off, however there is a wide spectrum of implements and attachments that do.

Some examples of PTO powered implements used on a farm are hay mowers, rakes and balers, a brush hog which is a brush clearing attachment for a tractor, post hole attachment for tractors, just to name a few...

If you heat with wood than a firewood log splitter and a wood chipper attachment for tractors are extremely helpful to prepare for the coming winter's cold weather.

Some implements are especially helpful for weather related tasks, such as a power take-off generator attachment if the power goes out, power take-off water pumps when dealing with flooded areas, or snow blower tractor attachments to tackle winter snowfalls.

These are just a few examples of implements that are mechanized by the tractor's power take-off.

An important note while we're on the subject: When considering obtaining an implement, the tractor, PTO, hitch, and implement all need to have the same category rating to ensure that they are compatible with each other.

What is Power Take Off Design Advancements?

Over the years, the types of PTOs have been enhanced to be more "farmer friendly" or to meet specific needs. While we're focusing on the basics of what is power take-off, here are some related PTO terms that you may come across.

The Transmission PTO Shaft is the earliest and simplest form of power take-off.

The Live PTO works with the use of a two-stage clutch. Pressing the clutch half-way only disengages the transmission, removing risk involved when you are switching gears. Pressing all the way down will disengage the transmission and the PTO. This allows you to slow down or change gears while the PTO continues to operate.

The Independent PTO is a further development of the live (two-stage clutch) power take-off. This PTO can be activated even if you have stopped the tractor or if it is not moving, allowing it to work independently from the transmission clutch. This type of power take-off can be engaged using a lever or a button which facilitates control of the PTO.

The Reverse PTO allows you to turn in the reverse direction, to go counterclockwise, via a lever or button. This is is very helpful when operating implements which can get stuck such as a post hole digger or a thresher.

Why Are Spinning Power Take-Off Shafts Shaped Differently?

The differences in the shapes of a power take-off shaft depend on where they're made. To identify which you’re using, look at the shape of your shaft.

North American made shafts are available in 4 shapes: round,

square, rectangle, or splined.

Metric PTO shafts, which are European, are star-shaped. Bell-shaped,

or football-shaped.

Both parts of your spinning power take-off shaft will have the same shape since one fits inside the other, allowing for telescopic movement when being used.

What is Power Take Off Safety Issues?

Always Use Caution: PTO Can be Very Dangerous!

A power take-off is both extremely useful and very dangerous. Severe injury or death can result from accidents involving the power take-off. "According to the National Safety Council (USA) and Health & Safety Executive (HSE) (UK), a high percentage of tractor related fatalities in the USA & UK involved the PTO." Source Every year people are seriously injured or killed in accidents involving PTOs.

This is why understanding power take off safety is so vitally important!

Lack of caution when dealing with the strength of force of the PTO, the high speed of rotation, operator carelessness or error, and lack of proper guarding used on the equipment can result in life-changing injury or fatality.

Please take the time to watch this short but important video by the University of Minnesota Extension Farm Safety and Health covering the basics of PTO parts, hazards, and safety.

Visit here for more advice on power take-off safety.

A Bit of PTO History

It's not surprising that the power take-off unit was developed mainly through the ingenuity of farmers.

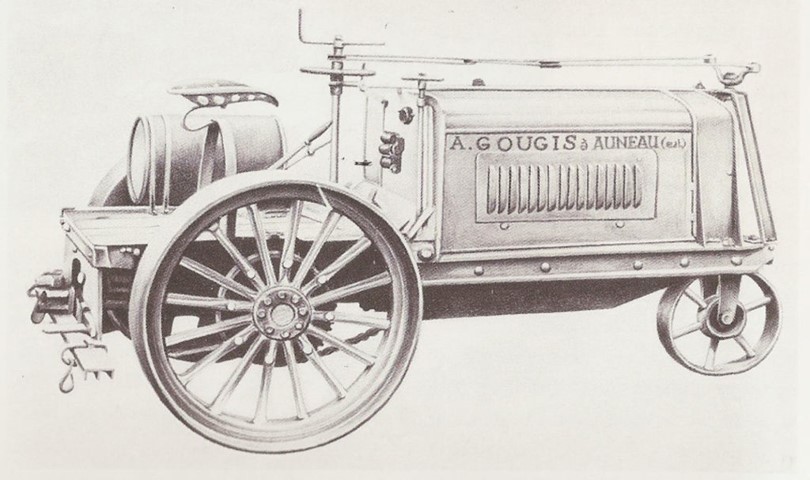

In 1906, Albert Gougis, a French farmer, mechanic, and a brilliant university professor, created the first power take-off of sorts. He developed a mechanical power take-off to transmit the rotary motion of the engine to the mechanisms of a harvester.

His home-built tractor had a chain running from the engine's crankshaft which connected to a McCormick implement. This mechanism could be engaged separately from the clutch, allowing the tractor to both pull and empower the implement. Several universal joints aided in the flexibility of the shaft.

Several years later, while in France, Mr. Edward A. Johnston, an engineer working with the International Harvester Company, was inspired by Albert Gougis' invention. He foresaw that this innovative device could supply power from the tractor's engine to many unpowered, but very useful implements. In 1918, the International Harvester Company added the first built-in power take-offs to some of its 8-16 HP model tractors.

Two years later, in 1920, International Harvester presented their 25-30 HP tractor with PTOs. And soon after, PTOs began to be commonly seen in other makes of tractors as well.

The first industry standard for the design power take-offs was adopted by the American Society of Agricultural Engineers in April 1927. The PTO's rotational speed was specified as 536 ± 10 rpm, the rotational direction being clockwise. The speed was later changed to 540 rpm.

Little did Monsieur Albert Gougis, the French farmer, know how his ingenious, homemade contraption would be so revolutionary and a great boon to farmers around the world for generations to come!

Translate This Page!

Traduire Cette Page!

¡Traduzca Esta Pagina!

Piping Rock©

Bringing you the highest quality In hundreds of health care and life-enhancing natural products at the

lowest cost to you!

high reviews, crazy deals,

happy, healthy customers!

Click here and save today!

Business Appreciation

* This website is not affiliated with

Piping Rock

Supporting our local feed mills

Meunerie Alexandria Milling

613-525-1973

Great Products • Great Prices

Great Service

Click the pic for their

facebook page!

Meunerie Alexandria Milling

Established in 1962 by The Massie Family

Email: Alexandriamilling@hotmail.Ca

475 Massie Crescent

Alexandria, Ontario, Canada

~~~

Small Business Appreciation

* This website is not affiliated with

Meunerie Alexandria Milling